This is a list of the ultimate tool setup for a beginner bricklayer. The best bricklaying tools you can buy and why you need to have them in your kit.

Are you starting a new bricklaying apprenticeship and needing to put together your first toolkit. Wondering what hand tools you will need before arriving at site or college? What sizes to get? And what brands to buy?

First thing you need to know is bricklayers are very proud of their tools. They normally stick with tools brands they know and trust. If you buy good quality gear and look after it, your tools will last ages. Remember the quality and condition of a bricklayers tools is a good indication of their work and attitude.

There are some great tool making companies that specialize in bricklaying tools. Many of them do sell ready made apprentice kits. However I wouldn't recommend these kits for a few reasons.

Firstly I haven't seen one with the right masonry tools you will need. They miss some of the must have tools but then add random stuff you don't need, (margin trowels?) Another reason is you want to select the best brand for the tool you need rather than just sticking to one brand.

In the following list, I give my picks for the best bricklaying tools you can get. As you progress through your apprenticeship and bricklaying career, no doubt you will find tools that suit your personal taste and style. Also you will need to eventually buy a few more hand tools for more specific work, these are not used so frequently. The tool list here is a safe start. It will focus on the most common bricklaying tools, so you are able to put together a basic tool kit.

I'll try to stick to tools that are friendly for a beginner bricklayer and are easily picked up in America, Canada, the UK and Australia. Although I will try to recommend only one brand of tool, there maybe good alternatives worth checking out.

Start Up Bricklayers Tool List

1) Toolbox - Dewalt Tough System Extra Large (DS400)

Check out more details and the Price here

Let's start with how you'll keep all your tools together. The traditional way is in a tool bag or just a bucket. I think having a proper Toolbox is the way to go though. It easy to organize and keeps your tools secure and dry.

The Extra Large Dewalt Tool Box is the perfect box.

- Height 410mm 16 1/8 inches

- Length 554mm 21 3/4 inches

- Width 366mm 14 3/8 inches

Alternatively:

If you really want something a little larger, go with another Dewalt box this time with wheels and part of the Tstak modular system.DEWALT Tool Box with Wheels TSTAK Deep Box

2) Brick Trowel - Marshalltown The Premier Line Philadelphia 10" DuraSoft

Check out more details and the Price here

The bricklayers most important tool is his brick trowel. To get one that feels right, you will need to consider four things:

- Size of blade

- Pattern of blade

- Handle type

- Brand of trowel

If you are a beginner bricklayer it will be best to start with a small trowel. Because the best trowels are made in America, the sizes are in inches. 9" and 10" are small trowels, 11" and 12" are medium trowels 13" and above are large trowels. Go with a 10 inch trowel as it will be easier to control. As you gain more experience you may opt for something larger especially if you lay a lot of block.

Two main blade patterns are the London and Philadelphia. A Philadelphia trowel enables more mortar to be loaded, since you are starting with a small 10 inch blade select the Philadelphia pattern. Have a look here for more information on brick trowel patterns.

The grip provided by the synthetic rubber handles are the best for an apprentice bricklayer.

When it come to selecting the trowel maker, there are only two real options. I give the edge slightly to Marshalltown, their trowels have great flexibility and weight balance.

With time you may want to look at picking up another brick trowel, one for bricklaying and one for laying blocks. Have a look at what I use here.

Update: You might want to consider checking out one of the new Cork handled Brick Trowels - See a review of the Marshalltown and W.Rose here.

The other brand is W.Rose. Their premium brick trowel is a great choice. It's made super tough. Click here for a closer look at the many options for full tang brick trowel brands.

Check out more details and the Price here

There really is only one level maker you should use, the German company Stabila. Although not always admitting it, bricklayers tend to be quite tough on their spirit levels. The Stabila is so well made it can take a lot of the abuse and still read true.

The 48" 1200mm Spirit Level is perfect for building up corners and making sure that the bricks run in line. This will be your most used level so get a good one. For information on the best levels to use for bricklaying see here.

Check out more details and the Price here

It's definitely worth having a smaller spirit level for tight situations, where your main 48" 1200mm level can't fit. For my secondary level I have had different lengths over the years, but I have settled on the 24" 600mm length as it is the most versatile small level.

Again I would recommend Stabila for your smaller level. They do make the masonry padded version and the R-Beam in this size as well, but too be honest they are both a bit unnecessary. Just stick with the Heavy Duty Type 196, the one with the hand holes.

Check out more details and the Price here

The final Level you will need is a boat level also called a torpedo level. This very small spirit level will not be used all the time, but will be necessary for detailed work and solider courses. Most bricklaying colleges or pre-trade courses will get you to do this type of work so it would be best to have a boat level with you.

Because it's basically used for delicate work, you could definitely get away with buying a cheaper boat level. However if you want the best boat level, buy a Stabila again.

Check out more details and the Price here

It's pretty rare to cut bricks with a hammer these days, however a brick hammer gets used to tidy cuts that go a bit wrong with the bolster. If you purchase a brick hammer you could get away not having a claw hammer. Many bricklayers will use their brick hammer to drive in nails or even their line pins into a hard wall. There is a variation called a scutch hammer which has replaceable front teeth. Don't bother with these as you won't be using it as much as they did in the old days.

Like their claw hammers Estwing make a great brick hammer. It has good balance and stays sharp for a long time. Estwing has a good range of weights to choose from, there is no need to go to heavy, stick with one under 20 Ounces.

Check out more details and the Price here

A pointing trowel looks just like a normal brick trowel only smaller, and it's made in the same way. You'll use your pointing trowel for multiple things, for struck and weathered jointing, for filling in joints, for spreading mortar in tight places, and for cleaning of hard mortar.

Most bricklayers will use the 6" pointing trowels, the smaller 4" and 5" ones are favored by archaeologists. Marshalltown pointing trowels are made to same high standard as their brick trowels.

Check out more details and the Price here

The flat tuck pointers (sometimes called caulking trowels) are needed to smooth out and seal the mortar on raked joints. They can also be used to push mortar into empty holes in the brickwork. This is needed when you are doing brick repairs to a wall.

The pointers do get a lot use, so they will wear down, becoming smaller in width. The Marshalltown tuck pointers have been the most durable I've used. Wooden handles would be most common but the DuraSoft handles are really nice to use.

Check out more details and the Price here

You will eventually need different sizes of tuck pointers. Two important size widths to get straight away are the 10mm 3/8" and the 8mm 5/16". These two Marshalltown Pointers should cover most situations during your apprenticeship.

Check out more details and the Price here

The concave joint is a main joint type in block and brick masonry. It's commonly done with a half round "S" bend jointer. However I recently switched to a barrel jointer and feel it leaves a cleaner finish.

Hubbard have specialized in jointers for 50 years. If you ask around some brickies have had their Hubbard jointers for over 30 years, they last forever. Their barrels come in 4 interchangeable sizes, 1/2″ 13mm, 5/8″ 16mm, 3/4″ 19mm, 7/8″ 22mm, so no matter the joint size, you'll have the right diameter half round.

Check out more details and the Price here

Again a tool with multiple names depending on where you live:

The Ox raker might be a little controversial as it has poly wheels on it. By far the majority of rakers have aluminum or steel wheels. However I find the poly wheeled raker so much better to use, they roll nicely on the brick and don't make noise. My one has lasted years 8 years now and still going strong.

I did notice it gets some bad reviews however keep in mind many DIY'ers buy these rakers thinking they will be able to clean out mortar joints that are 30 years old, no wonder the nail doesn't last one day. Rakers do not scrape out hard mortar joints.

Check out more details and the Price here

A builders square or set square is vital for building brick pillars and setting out returns. It helps you mark out cuts that must stay square.

It's not too important which square you get, however the Irwin framing square is a good one. It's aluminum so it doesn't rust and is light. The high visibility markings are great to read.

Check out more details and the Price here

Having a soft brush will help you put the finishing touches on your brickwork. After jointing a light brush will clean off the small dags that form on the edges.

To keep this process fast, don't get a small paint brush style brush. Go for one that is a long as possible and has a handle that won't scrape your knuckles. The Marshalltown beaver tail brush is a great choice.

Check out more details and the Price here

A steel rule is good for mark bricks that need to be cut, you can mark with a tape measure of course, but the reason I will use a rule is because it's not damaged by water. If you need to remark after using a wet saw or even if it starts raining, a rule will get wet but it doesn't matter.

Mitutoyo is an old Japanese company that has been around for ages. Their stainless steel rules are used extensively in the engineering industry. They are a great addition to your toolkit.

Check out more details and the Price here

With your steel rule dedicated to measuring cuts to the bricks and blocks, you can look after your tape measure. It probably will need to be replaced every few years still as gets used often to measure the length and height of walls, mark gauge rods and the like.

You don't really want a tape measure to be longer than 10m 33 foot it's too big and bulky, for longer setting out measurements it's better to have the manual wind up style tape.

The Komelon High-Visibility Tape Measure is very well made and easy to read. Don't buy one that has both millimetres and inches, that just renders one side of your useless for the majority of the time.

Alternatively:

Another great tape measure to check out is the Stanley Fatmax Auto-Lock Tape Rule.

Check out more details and the Price here

A sliding T bevel won't be used too often but you will need to buy one early. Many of the detailed projects made at a bricklayers college or pre-trade course will require a bevel to accurately mark angled cuts.

Shinwa is another Japanese company that makes great measuring equipment. Their aluminum and stainless steel sliding bevels don't break or warp like the cheap plastic ones. And once it's tighten up it stays locked in place.

Check out more details and the Price here

A good set of pencils are a must for being able to cut and setup brick walls accurately.

The Irwin Pencils work really well on masonry, they can be sharpened to a nice point and then hold their sharpness longer than other pencil brands I've used. Even if you sharpen the lead quite long it doesn't break.

Check out more details and the Price here

You have to be able to keep your pencils sharp and open up packages of bricks and blocks. Having a good sliding knife on you is really handy.

The Tajima Rock Hard series have cheap replacement blades that are easy to put in. The knife is a great comfortable size and cuts well.

Check out more details and the Price here

Line pins fix the string line between two brick corners. They are most commonly used on existing brickwork were repairs need to be done. The pins are driven into the hard mortar with a hammer.

Because the pins need to be driven into hard mortar you do need pins that are tough. The Footprint line pins are the way to go. Trusted by bricklayers all over the world they are basically indestructible.

Check out more details and the Price here

A string line used to lay bricks and blocks needs to be strong. They get pulled tight to remove any sag from the line. When they do break it's best not to try and tie them together again.

The new Ox cyan lines have surprisingly good contrast. But the real reason like these lines is that they are super thin and still really strong. With a thin string line it makes it easier for beginner bricklayers to keep laid bricks off it.

Check out more details and the Price here

The line blocks hold the string line to a brick corner or a profile. Wooden ones are cheaper but they do break. Be careful with smaller blocks which can put a lot of pressure on a freshly built corners.

Not simply to match the blue Ox string line, I really like the Ox rubber line blocks. They are strong, are the perfect size and have really good grip.

Check out more details and the Price here

You will need a club or lump hammer to use with your bolsters and chisels. A lighter hammer for this purpose will be fine, however there will be times were a heavier hammer is beneficial, such as driving in steel reinforcing bar. A great balance is the 3 pound club hammer.

There are many companies that make adequate club hammers. But when it comes to hammers I always favor Estwing. It has a comfortable handle designed for long periods of use.

Check out more details and the Price here

Most new bricks will be cut with a brick saw. However old recycled bricks or bricks that don't require a high level finish typically get cut with a hammer and bolster. The 100mm 4" bolster is the most common size, it has a lot of weight behind it to give a nice clean cut and it's wide enough to cover most bricks.

I have used many bolsters that pack up quickly. It is worth getting the best. I recommend the Footprint Bolsters, like their line pins they are high quality.

Check out more details and the Price here

A scrub brush will last you a few years before you need to replace it. I know there are many brickies that won't clean their gear until the next day, but I think it's best at the end of the day. I do use water on most of my tools, scrubbing off the mortar, then any of my carbon steel tools like my brick trowel and pointers I will dry off with a rag. If you ever need to use a brush with acid this type works well, especially for efflorescence removal.

The Carlisle Sparta scrub brush has nice long bristles that a firm enough for a quick clean.

Check out more details and the Price here

For any power tool use even hammering make sure you have good hearing protection. Most commercial sites will require hard hats so it's worth having a pair of clip-on ear muffs. But having an over head pair is also needed for when you are not wearing your hard hat.

The 3m peltor 4xa ear muffs have a noise reduction rating (NRR) of 27 dB for moderate to high noise exposures. They are lightweight and have a slim-profile making them easy to wear for long periods.

Check out more details and the Price here

You will also need a good pair of safety glasses when cutting, hammering or using other power tools. Get clear ones rather than tinted so you can see clearly with you loose light.

The No Cry Safety Glasses are anti-fog and scratch resistant making them perfect for the rigours of bricklaying.

Check out more details and the Price here

Gloves are certainly not a necessary part of a bricklayers Tool kit, however for someone that has had too much experience laying brick it is a good idea to look after your hands. Your hands do toughen with time but there are certain brick types that its always best to wear gloves for.

Dex Fit Gloves are nice and thin giving good movement and feeling but still provide the needed protection for a brick mason.

This is the Tool List of bricklaying tools I would be using if I was starting my masonry apprenticeship again. It's not going to be perfect for everyone. As you gain experience you will start to work out what works for you. Hope this list is a good start for you though.

Update: You might want to consider checking out one of the new Cork handled Brick Trowels - See a review of the Marshalltown and W.Rose here.

Alternatively:

The other brand is W.Rose. Their premium brick trowel is a great choice. It's made super tough. Click here for a closer look at the many options for full tang brick trowel brands.

3) 48" 1200mm Spirit Level - Stabila Heavy Duty Type 196

Check out more details and the Price here

There really is only one level maker you should use, the German company Stabila. Although not always admitting it, bricklayers tend to be quite tough on their spirit levels. The Stabila is so well made it can take a lot of the abuse and still read true.

The 48" 1200mm Spirit Level is perfect for building up corners and making sure that the bricks run in line. This will be your most used level so get a good one. For information on the best levels to use for bricklaying see here.

4) 24" 600mm Spirit Level - Stabila Heavy Duty Type 196

Check out more details and the Price here

It's definitely worth having a smaller spirit level for tight situations, where your main 48" 1200mm level can't fit. For my secondary level I have had different lengths over the years, but I have settled on the 24" 600mm length as it is the most versatile small level.

Again I would recommend Stabila for your smaller level. They do make the masonry padded version and the R-Beam in this size as well, but too be honest they are both a bit unnecessary. Just stick with the Heavy Duty Type 196, the one with the hand holes.

5) 10" 250mm Boat Level - Stabila 25100

Check out more details and the Price here

The final Level you will need is a boat level also called a torpedo level. This very small spirit level will not be used all the time, but will be necessary for detailed work and solider courses. Most bricklaying colleges or pre-trade courses will get you to do this type of work so it would be best to have a boat level with you.

Because it's basically used for delicate work, you could definitely get away with buying a cheaper boat level. However if you want the best boat level, buy a Stabila again.

6) Brick Hammer - Estwing Bricklayers / Masons Hammer 20oz

Check out more details and the Price here

It's pretty rare to cut bricks with a hammer these days, however a brick hammer gets used to tidy cuts that go a bit wrong with the bolster. If you purchase a brick hammer you could get away not having a claw hammer. Many bricklayers will use their brick hammer to drive in nails or even their line pins into a hard wall. There is a variation called a scutch hammer which has replaceable front teeth. Don't bother with these as you won't be using it as much as they did in the old days.

Like their claw hammers Estwing make a great brick hammer. It has good balance and stays sharp for a long time. Estwing has a good range of weights to choose from, there is no need to go to heavy, stick with one under 20 Ounces.

Alternatively:

Vaughan ABL18 18-Oz Bricklayers Hammer is another well balanced brick hammer.7) Pointing Trowel - Marshalltown 6" The Premier Line

Check out more details and the Price here

A pointing trowel looks just like a normal brick trowel only smaller, and it's made in the same way. You'll use your pointing trowel for multiple things, for struck and weathered jointing, for filling in joints, for spreading mortar in tight places, and for cleaning of hard mortar.

Most bricklayers will use the 6" pointing trowels, the smaller 4" and 5" ones are favored by archaeologists. Marshalltown pointing trowels are made to same high standard as their brick trowels.

8) 10mm 3/8 Flat Tuck Pointer - Marshalltown The Premier Line

Check out more details and the Price here

The flat tuck pointers (sometimes called caulking trowels) are needed to smooth out and seal the mortar on raked joints. They can also be used to push mortar into empty holes in the brickwork. This is needed when you are doing brick repairs to a wall.

The pointers do get a lot use, so they will wear down, becoming smaller in width. The Marshalltown tuck pointers have been the most durable I've used. Wooden handles would be most common but the DuraSoft handles are really nice to use.

9) 8mm 5/16 Flat Tuck Pointer - Marshalltown The Premier Line

Check out more details and the Price here

You will eventually need different sizes of tuck pointers. Two important size widths to get straight away are the 10mm 3/8" and the 8mm 5/16". These two Marshalltown Pointers should cover most situations during your apprenticeship.

10) Barrel Jointer - Hubbard Barrel Jointer

Check out more details and the Price here

The concave joint is a main joint type in block and brick masonry. It's commonly done with a half round "S" bend jointer. However I recently switched to a barrel jointer and feel it leaves a cleaner finish.

Hubbard have specialized in jointers for 50 years. If you ask around some brickies have had their Hubbard jointers for over 30 years, they last forever. Their barrels come in 4 interchangeable sizes, 1/2″ 13mm, 5/8″ 16mm, 3/4″ 19mm, 7/8″ 22mm, so no matter the joint size, you'll have the right diameter half round.

Alternatively:

If you can't get your hands on a Hubbard try the Amtech G1700 Jointer.11) Chariot Raker - OX Tools Poly Wheel

Check out more details and the Price here

Again a tool with multiple names depending on where you live:

- Chariot Raker

- Roller Raker

- Wheel Raker

- Skate Raker

- Joint Raker

The Ox raker might be a little controversial as it has poly wheels on it. By far the majority of rakers have aluminum or steel wheels. However I find the poly wheeled raker so much better to use, they roll nicely on the brick and don't make noise. My one has lasted years 8 years now and still going strong.

I did notice it gets some bad reviews however keep in mind many DIY'ers buy these rakers thinking they will be able to clean out mortar joints that are 30 years old, no wonder the nail doesn't last one day. Rakers do not scrape out hard mortar joints.

12) Builders Square - Irwin framing square 24" × 16"

Check out more details and the Price here

A builders square or set square is vital for building brick pillars and setting out returns. It helps you mark out cuts that must stay square.

It's not too important which square you get, however the Irwin framing square is a good one. It's aluminum so it doesn't rust and is light. The high visibility markings are great to read.

13) Soft Brush - Marshalltown Masonry Brush Beaver Tail

Check out more details and the Price here

Having a soft brush will help you put the finishing touches on your brickwork. After jointing a light brush will clean off the small dags that form on the edges.

To keep this process fast, don't get a small paint brush style brush. Go for one that is a long as possible and has a handle that won't scrape your knuckles. The Marshalltown beaver tail brush is a great choice.

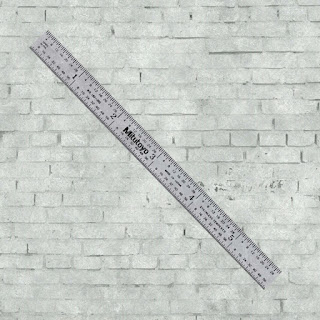

14) Steel Rule - Mitutoyo 182-126 Steel Rule 12"/300mm

Check out more details and the Price here

A steel rule is good for mark bricks that need to be cut, you can mark with a tape measure of course, but the reason I will use a rule is because it's not damaged by water. If you need to remark after using a wet saw or even if it starts raining, a rule will get wet but it doesn't matter.

Mitutoyo is an old Japanese company that has been around for ages. Their stainless steel rules are used extensively in the engineering industry. They are a great addition to your toolkit.

15) Tape Measure 10m 33 foot- Komelon High-Visibility Professional Tape

Check out more details and the Price here

With your steel rule dedicated to measuring cuts to the bricks and blocks, you can look after your tape measure. It probably will need to be replaced every few years still as gets used often to measure the length and height of walls, mark gauge rods and the like.

You don't really want a tape measure to be longer than 10m 33 foot it's too big and bulky, for longer setting out measurements it's better to have the manual wind up style tape.

The Komelon High-Visibility Tape Measure is very well made and easy to read. Don't buy one that has both millimetres and inches, that just renders one side of your useless for the majority of the time.

Alternatively:

Another great tape measure to check out is the Stanley Fatmax Auto-Lock Tape Rule.

16) Sliding T Bevel - Shinwa 8" Blade

Check out more details and the Price here

A sliding T bevel won't be used too often but you will need to buy one early. Many of the detailed projects made at a bricklayers college or pre-trade course will require a bevel to accurately mark angled cuts.

Shinwa is another Japanese company that makes great measuring equipment. Their aluminum and stainless steel sliding bevels don't break or warp like the cheap plastic ones. And once it's tighten up it stays locked in place.

17) Pencils - Irwin Carpenter Pencil Medium Lead

Check out more details and the Price here

A good set of pencils are a must for being able to cut and setup brick walls accurately.

The Irwin Pencils work really well on masonry, they can be sharpened to a nice point and then hold their sharpness longer than other pencil brands I've used. Even if you sharpen the lead quite long it doesn't break.

18) Utility Knife - Tajima Rock Hard Snap Knife

Check out more details and the Price here

You have to be able to keep your pencils sharp and open up packages of bricks and blocks. Having a good sliding knife on you is really handy.

The Tajima Rock Hard series have cheap replacement blades that are easy to put in. The knife is a great comfortable size and cuts well.

19) Line Pins - Footprint 6"

Check out more details and the Price here

Line pins fix the string line between two brick corners. They are most commonly used on existing brickwork were repairs need to be done. The pins are driven into the hard mortar with a hammer.

Because the pins need to be driven into hard mortar you do need pins that are tough. The Footprint line pins are the way to go. Trusted by bricklayers all over the world they are basically indestructible.

20) String Line - OX Builders Line

Check out more details and the Price here

A string line used to lay bricks and blocks needs to be strong. They get pulled tight to remove any sag from the line. When they do break it's best not to try and tie them together again.

The new Ox cyan lines have surprisingly good contrast. But the real reason like these lines is that they are super thin and still really strong. With a thin string line it makes it easier for beginner bricklayers to keep laid bricks off it.

21) Line Blocks - OX Rubber Line Blocks

Check out more details and the Price here

The line blocks hold the string line to a brick corner or a profile. Wooden ones are cheaper but they do break. Be careful with smaller blocks which can put a lot of pressure on a freshly built corners.

Not simply to match the blue Ox string line, I really like the Ox rubber line blocks. They are strong, are the perfect size and have really good grip.

22) Club Hammer - Estwing 3-Pound

Check out more details and the Price here

You will need a club or lump hammer to use with your bolsters and chisels. A lighter hammer for this purpose will be fine, however there will be times were a heavier hammer is beneficial, such as driving in steel reinforcing bar. A great balance is the 3 pound club hammer.

There are many companies that make adequate club hammers. But when it comes to hammers I always favor Estwing. It has a comfortable handle designed for long periods of use.

23) Brick Bolster - Footprint Bolster 100mm (4in)

Check out more details and the Price here

Most new bricks will be cut with a brick saw. However old recycled bricks or bricks that don't require a high level finish typically get cut with a hammer and bolster. The 100mm 4" bolster is the most common size, it has a lot of weight behind it to give a nice clean cut and it's wide enough to cover most bricks.

I have used many bolsters that pack up quickly. It is worth getting the best. I recommend the Footprint Bolsters, like their line pins they are high quality.

24) Scrub Brush - Carlisle Sparta Spectrum Utility Brush

Check out more details and the Price here

A scrub brush will last you a few years before you need to replace it. I know there are many brickies that won't clean their gear until the next day, but I think it's best at the end of the day. I do use water on most of my tools, scrubbing off the mortar, then any of my carbon steel tools like my brick trowel and pointers I will dry off with a rag. If you ever need to use a brush with acid this type works well, especially for efflorescence removal.

The Carlisle Sparta scrub brush has nice long bristles that a firm enough for a quick clean.

25) Earmuffs - 3m Peltor 4xa

Check out more details and the Price here

For any power tool use even hammering make sure you have good hearing protection. Most commercial sites will require hard hats so it's worth having a pair of clip-on ear muffs. But having an over head pair is also needed for when you are not wearing your hard hat.

The 3m peltor 4xa ear muffs have a noise reduction rating (NRR) of 27 dB for moderate to high noise exposures. They are lightweight and have a slim-profile making them easy to wear for long periods.

26) Safety Glasses - No Cry Safety Glasses

Check out more details and the Price here

You will also need a good pair of safety glasses when cutting, hammering or using other power tools. Get clear ones rather than tinted so you can see clearly with you loose light.

The No Cry Safety Glasses are anti-fog and scratch resistant making them perfect for the rigours of bricklaying.

27) Gloves - Dex Fit Level 5 Cut Resistant Gloves

Check out more details and the Price here

Gloves are certainly not a necessary part of a bricklayers Tool kit, however for someone that has had too much experience laying brick it is a good idea to look after your hands. Your hands do toughen with time but there are certain brick types that its always best to wear gloves for.

Dex Fit Gloves are nice and thin giving good movement and feeling but still provide the needed protection for a brick mason.

Bricklaying Tool List - the Apprentices Ultimate Guide

- Toolbox - Dewalt Tough System Extra Large (DS400)

- Brick Trowel - Marshalltown The Premier Line Philadelphia 10" DuraSoft

- Spirit Level 48" 1200mm - Stabila Heavy Duty Type 196

- Spirit Level 24" 600mm - Stabila Heavy Duty Type 196

- Boat Level 10" 250mm - Stabila 25100

- Brick Hammer - Estwing 20oz

- Pointing Trowel - Marshalltown 6" The Premier Line

- Tuck Pointer 10mm 3/8 - Marshalltown The Premier Line

- Tuck Pointer 8mm 5/16 - Marshalltown The Premier Line

- Barrel Jointer - Hubbard Barrel Jointer

- Chariot Raker - OX Tools Poly Wheel

- Builders Square - Irwin framing square 24" × 16"

- Soft Brush - Marshalltown Masonry Brush Beaver Tail

- Steel Rule - Mitutoyo 182-126 Steel Rule 12"/300mm

- Tape Measure 10m 33" - Komelon High-Visibility Professional Tape

- Sliding T Bevel - Shinwa 8" Blade

- Pencils - Irwin Carpenter Pencil Medium Lead

- Utility Knife - Tajima Rock Hard Snap knife

- Line Pins - Footprint 6"

- String Line - OX Builders Line

- Line Blocks - OX Rubber Line Blocks

- Club Hammer - Estwing 3-Pound

- Brick Bolster - Footprint Bolster 100mm (4in)

- Scrub Brush - Carlisle Sparta Spectrum Utility Scrub Brush

- Earmuffs - 3m Peltor 4xa

- Safety Glasses - No Cry Safety Glasses

- Gloves - Dex Fit Level 5 Cut Resistant Gloves

This is the Tool List of bricklaying tools I would be using if I was starting my masonry apprenticeship again. It's not going to be perfect for everyone. As you gain experience you will start to work out what works for you. Hope this list is a good start for you though.