A new material is now being used for brick trowel handles - a composite Cork blend. The interesting thing is that both Marshalltown and W.Rose (Kraft tools), the heavy weights in the brick trowel industry, have released a whole lineup of them for their premier brick trowels. Both released their range in 2019.

Marshalltown call theirs the DuraCork Handle and W.Rose the Elite Series Cork Handle.

I have used many handle types over the years but the two I have settled on is Marshalltowns DuraSoft and W.Rose ProForm, both of them are the soft grip options. For more on the Two Brick Trowels I'm currently using See Here.

Now when it comes to fishing rods however I'll take the cork handles over synthetics any day, so I'm looking forward to giving the two cork handled Bricklayers Trowels ago.

Marshalltown and W. Rose Cork handles Review

So you know I haven't purchased the Marshalltown DuraCork or the W. Rose Elite Series Cork Handle trowels yet, but as it happens I know some fellow bricklayers that have. After a good few hours of laying with both of them, here are my thoughts.

"My next trowel will have a Cork handle"

The blade construction, balance and shank angle of both the W.Rose and Marshalltown are the same as their other trowels. If they are a bit different to what I currently using, I didn't notice.

To be honest I was skeptical at first about the cork handles, thinking they would be a bit delicate on a brick trowel. However what I've seen of both trowel brands so far has really impressed.

Why use a Brick Trowel with a cork handle?

- Comfort

- Grip

- Shockproof

- Dust-proof

- Durable

- Waterproof

Comfort

Being made with cork, the handles have a natural softness, making them easy to hold and ergonomic. They are designed to be used comfortably all day with no chafing despite the grip. The W.Rose seems slightly wider and the Marshalltown longer.Grip

One of the strongest attributes of the cork handles is the grip they provide. When using gloves on other handle types like the plastic and soft grip handles it can be a bit slippery, especially when things are wet. The new cork handles provide excellent grip no matter how wet it gets, gloves or no gloves.Shockproof

The trowels handles are designed to resist vibrations. Cutting or tapping bricks can be done with limited fatigue. This would be good for anyone struggling with elbow or wrist injuries.Dust-proof

The handles don't absorb dust, so they won't stain and are easily cleaned. At the end of the day I checked the performance of both the Marshalltown and the W. Rose and they cleaned up like new.Durable

This one is obviously a little harder to test without time but both companies have advertised the durability of their new trowel handles. Both have heavy-duty urethane end caps for further protection. I'm sure there are still many bricklayers that still use the end of their trowel handle to hit bricks and all sorts of things.Waterproof

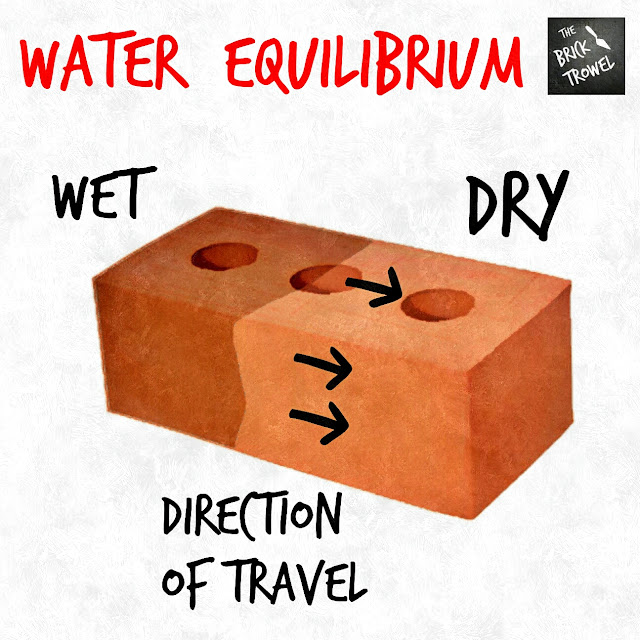

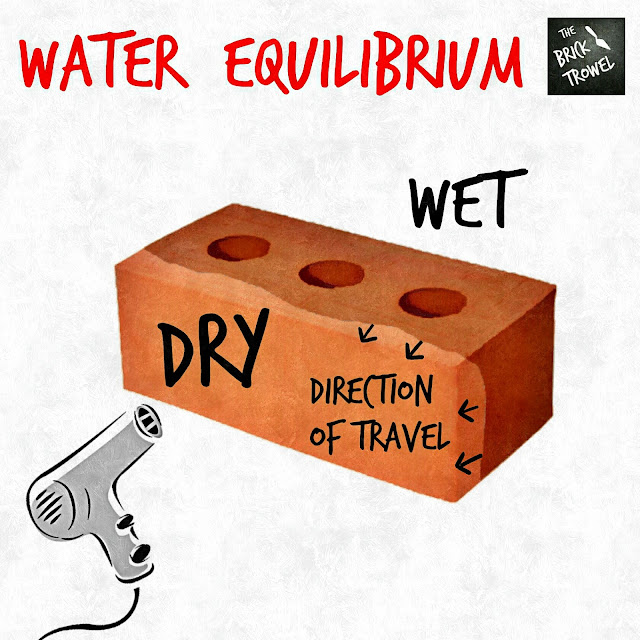

The cork has natural waterproofing properties meaning it sheds water rather than soaking it up. So the new cork handles dry faster, leading to better grip and durability.Available Cork Handle Options:

Marshalltown DuraCork Handle

Click here to see the Price

London Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 13"

Wide London Pattern - Sizes: 10.5" 11" 12"

Philadelphia Pattern - Sizes: 9.5" 10" 10.5" 11" 11.5" 12"

Wide London Pattern - Sizes: 10.5" 11" 12"

Philadelphia Pattern - Sizes: 9.5" 10" 10.5" 11" 11.5" 12"

W.Rose Elite Series Cork Handle

Narrow London Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 12.5" 13"

Wide London Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 12.5" 13"

Philadelphia Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 12.5" 13"

* Also comes in the Limber option giving more flexibility to the blade.

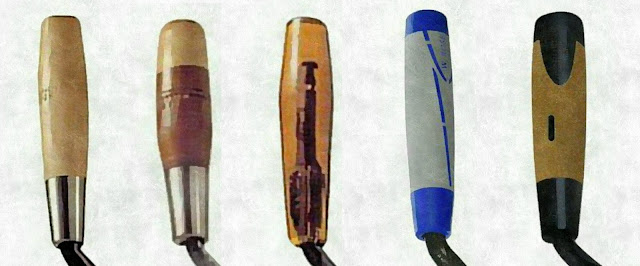

There are now five main types of brick trowel handles:

For more information on trowel materials and patterns see the article on what type of bricklaying trowel should I buy?

Wide London Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 12.5" 13"

Philadelphia Pattern - Sizes: 9" 9.5" 10" 10.5" 11" 11.5" 12" 12.5" 13"

* Also comes in the Limber option giving more flexibility to the blade.

Handle types:

There are now five main types of brick trowel handles:

- Wood

- Leather

- Plastic

- Soft Grips

- Composite Cork (New)

For more information on trowel materials and patterns see the article on what type of bricklaying trowel should I buy?

Wood Handles:

The most traditional of brick trowel handles. It wears really well, but is not the most comfortable or ergonomic. They do have a tendency to split when they get wet often.Leather Handles:

Very traditional and good looking handles, if I ever bought a ceremonial brick trowel it would have a leather handle. They are comfortable but do need to be cared for properly. Many W. Rose users have the leather handles.Plastic Handles:

An uncommon choice for a professional bricklayer. They have excellent durability. However they are very uncomfortable and can be slippery to use, especially when it's wet.Soft Grip Handles:

They are the most common handle these days and are often given a slick trademarked name. They are comfortable handles and give you great grip if you wear gloves. They do wear out if the handle is used for knocking bricks or levels.Composite Cork Handles:

The newest of the brick trowel handles. They are very comfortable to use and provide excellent grip for the bricklayer. My new recommended choice for bricklaying.If you are about to start an apprenticeship have a look at this article on how to put together your first tool kit.